Description

INNOSIL 300 APPLICATIONS & FUNCTIONS

- HTV Silicone Rubber, Liquid Silicone Rubber

- Paints and Coatings, Ink, Pigment

- Unsaturated polyester resins

- Adhesive & Sealant

- Rheology and thixotropy Control

- Used as anti-settling, thickening, anti-sagging agent

- Free Flow and Suspension for Powder

- Reinforcement

- Excellent transparency

INNOSIL 300 in Paints and Coatings

INNOSIL 300 fumed silica is mainly used in paints and coatings as thixotropic agent and anti-settling agent. It improves thixotropic and rheological properties of coatings and paint systems, retains original transparency of lacquers.

Furthermore, addition of fumed silica enhances hardening of coating film, adhesion to surfaces, as well as reduces deterioration rate of the coatings and fading of materials with transparent top coating. Besides, it helps to prevent run-off and sag of paints applied on vertical surfaces, thus ensuring top quality leveling. The fumed silica is used as a matting agent of lacquer systems, whereas the desired effect may be adjusted within wide ranges.

INNOSIL 300 in Adhesives and Sealants

INNOSIL 300 fumed silica is widely used in all kinds of adhesive and sealants industries, e.g. silicone sealants, PVC-plastisol sealant, polyacrylate sealant, epoxy adhesive, polyurethane adhesive, unsaturated polyester, polyurethane water-based adhesive, etc.

It is mainly used as additives for anti-sag, rheology control and anti-settling; also used as rheology control and reinforcing agents in sealants, and improves the storage stability and processability of adhesives and sealants.

INNOSIL 300 in RTV Silicone Sealant, HTV Silicone Rubber

INNOSIL 300 is an efficient reinforcement and rheology control additives for silicone rubber.

INNOSIL 300 fumed silica strengthens the cured rubber, increasing hardness, modulus, tensile strength and tear strength. Unlike other reinforcing fillers, it can be used in transparent or clear applications.

* Please refer to TDS, products selection guide, or contact us for applications advice and detailed usage info.

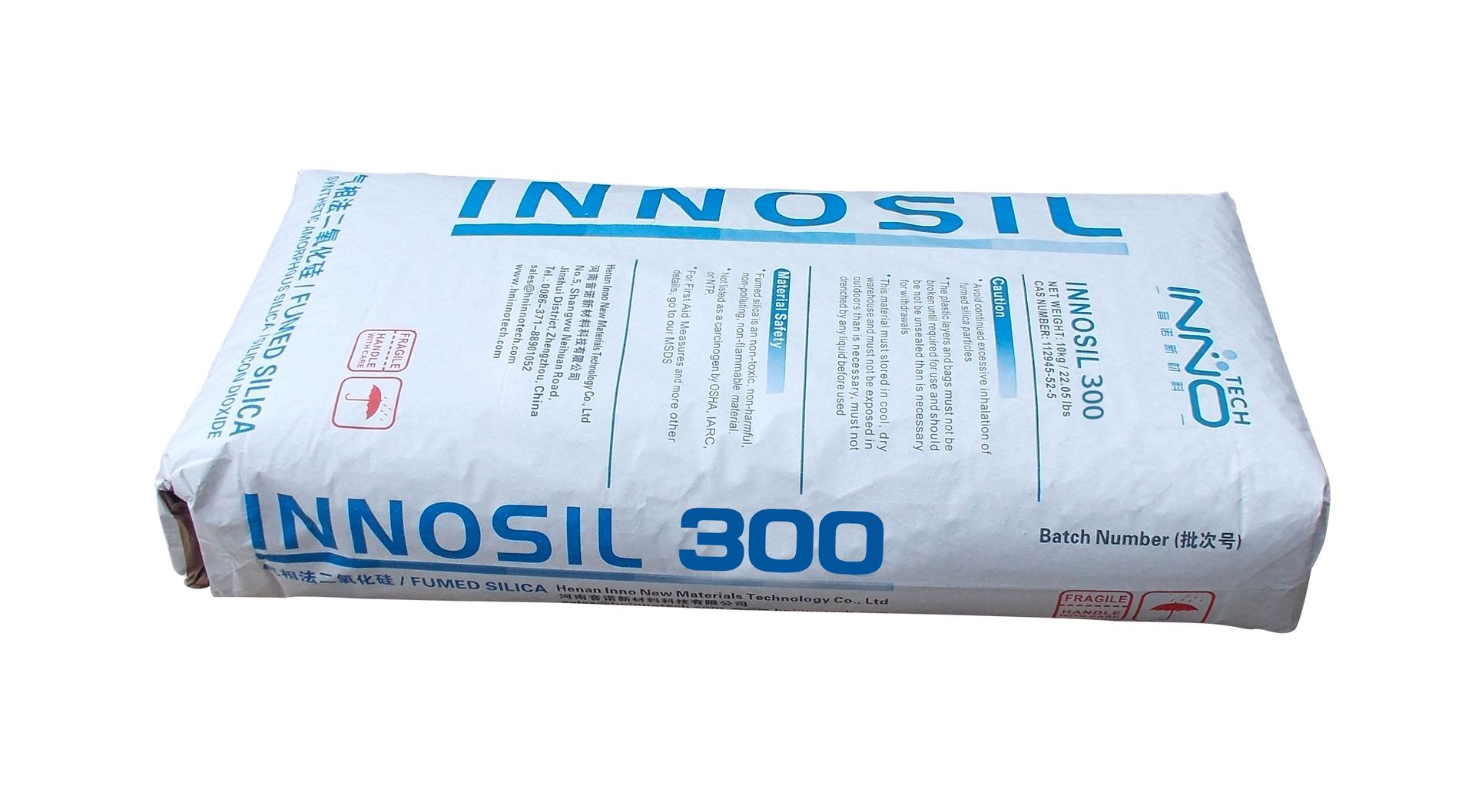

Packaging & Delivery of INNOSIL 300

Packaging

Due to its strong moisture-absorbing, fumed silica has strict requirement of moisture proofing. Our package meets this requirement:

- Products filled into the package by vacuum packing machine

- The bag is composed by three layer of kraft paper and one layer of plastic

- The bags are stacked on a pallet, with plastic layer(s) sealed around

Minimum Order Amount

Considering the package, transfer cost and other factors, we list suggest minimum order quantity for your reference:

- 10kg for aircraft

- Batch order: 1800kg(20ft container FCL) for sea shipping

- Small batch order: 180kg(1 pallet) for sea shipping

Details of Sea Shipping

1.8 tons

10 pallets

180KG/pallet

3.6 tons

20 pallets

180KG/pallet

4.0 tons

20 pallets

200KG/pallet

FAQ(Frequently Asked Questions)

1. How could I choose proper fumed silica product?

– Please tell us your application, our tech department will give professional advice;

– Provide the brand, grade of currently using fumed silica, we will find equivalent grade of INNOSIL fumed silica.

After that, we can provide samples for testing.

2. How to require samples, what’s the cost and time?

– Plese contact us for proper grades, and usually takes 1 to 7 days to prepare.

– Smaller amount of samples for lab test is totally free; While applicator need to pay the freight for larger amount

3. Delivery time

– The average delivery time is 7 to 14 days after receiving payment.